Klarm China Offers High-end Automated Digital Prototyping and Manufacturing

Jan 6, 2021

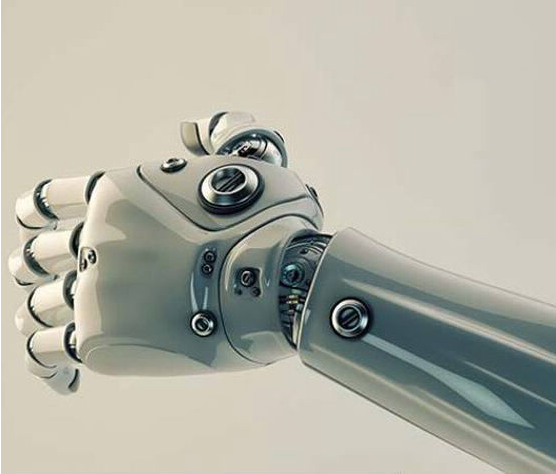

Guangzhou, Jan 6, 2021 (Issuewire.com) - Klarm Prototyping Limited is a factory that offers high precision automated digital prototyping and manufacturing, tooling, design, and production services. They have unique artistry and have extensive prototyping experience to accommodate virtually any machining or prototyping necessities. Also, they have large equipment and manufacturing capabilities aimed at bringing their customers' designs into reality.

Klarm Prototyping Limited provides our clients with fast and affordable pre-production feature prototypes aimed at giving them an actual competitive advantage over their rivals. It is an extremely excellent level of service to ensure their satisfaction and service, based on its high-en automated digital prototyping machines and CNC technologies.

A postprocessor for five-axis Fadal machining has been executed for the picked part as appeared in a professional China prototyping company.

In Metal / Plastic Prototyping Service, the utilization of CAD/CAM advances to produce G-and M-codes for CNC machine part creation is an essential part. This meeting examines a much further developed framework, a completely mechanized PC supported cycle arranging (CAPP) framework, or a generative CAPP framework. Cycle arranging makes an interpretation of plan data into the cycle steps and guidelines to productively and adequately fabricate items. As the planning cycle is upheld by numerous PC helped apparatuses, CAPP has advanced to rearrange and improve measure arranging and accomplish more viable utilization of manufacturing assets. Cycle arranging can generally be ordered into three classes- - manual, variant and generative. Manual cycle arranging depends on an assembling designer's understanding and information on creation offices, gear and capacities, measures, and tooling. A talented individual inspects a section attracting to build up the fundamental directions for measure arranging.

A cycle plan for a comparative part may be recovered and altered. Cycle arranging is very tedious and the outcomes fluctuate dependent on the individual doing the arranging. One rapid prototype from China can utilize variation and generative CAPP advancements for viable item prototyping and manufacturing.

Generative CAPP is a later type of process arranging, where process plans are grown consequently for each new workpiece. It begins from a CAD model and incorporates an assembling information base and rationale for dynamic. Man-made brainpower has additionally been added to these frameworks. A completely computerized generative CAPP framework will have the option to model or assembling an item with incredible advantages. To start with, as very little client collaboration is required, the model or part can be manufactured rapidly directly after the part's strong model is finished.

Second, as the configuration is completely attached to prototyping, fabricating, and other item improvement exercises, the data from the last stages can be web-based giving input to the strong demonstrating stage. For instance, when planning a component of an item, the data, for example, manufacturability and assembling cost can legitimately appear to the originator. The client would then be able to pick the ideal plan to lower. the prototyping or assembling cost. Along these lines, many process advancement issues can be settled in the item configuration stage, and in this way will enormously quicken the item improvement measure. In this manner, a generative CAPP framework will be one of the things to come prototyping frameworks as it will have the ability to bring all item advancement stages into the item definition stage and finding the ideal arrangement.

About Us

Klarm Prototyping Ltd is a company that offers innovative prototyping services to mainly focus on CNC machining and CNC machined parts. They have invested in our CNC infrastructure to ensure they have the volume and diversity required to run multiple jobs concurrently.

Media Contact

Lanny Larm

+86-20-3486-3083

http://www.rapidprototypechina.com/

Source :Guangzhou Klarm Prototyping Ltd

This article was originally published by IssueWire. Read the original article here.